Vetting Charter Vessels

Inspection and documentation programs can reduce cost and

improve safety on large marine construction projects

By Philip Woodcock

“Although a standard vetting system is not currently in use on the West Coast, the benefits will surely make this a shortcoming soon to be rectified.”

Two of the primary goals in a major marine construction project are safety and cost control. Now that the LNG Canada project has reached final investment decision, British Columbia will get to see a marine project on a scale unlike any other, and the BC maritime industry will see activity like never before. International activity from the developers, prime contractors and sub-contractors will require a large number of marine assets. Some of these assets will be imported by contractors if they cannot be sourced locally, and this will create significant challenges for the entire supply chain to provide fit-for-purpose vessels operated in a safe manner. Owners will find it difficult to supply vessels that meet the quality requirements of their clients if they do not have a standard to work towards. Clients, on the other hand, may be forced to accept or modify vessels at great expense to meet project requirements.

Each project will have marine professionals assigned with setting standards and approving vessels to work on site. This can result in different standards being applied across one project, let alone across several projects, making it challenging for vessel owners to know what to comply with. All of these factors could result in accepting sub-standard vessels out of necessity, or large amounts of money being spent trying to get vessels to comply. Who bears that cost will always be an awkward conversation between owner and charterer.

Flag State certification only shows that a vessel meets the minimum construction and safety standards set by Transport Canada, for example, and does not ensure that the vessel is fit for the purpose of the charter. In this case, the use of a standard vessel vetting system can ensure that owners know in advance what minimum operational, safety and quality standards are expected, and can ensure that all equipment is fit for purpose. This can also avoid unexpected costs that arise from the whims of an inspector. The clients, on the other hand, can ensure that they have access to a pool of pre-approved vessels that can be taken up at any time without having to do the inspection themselves. Owners and charterers then need only to negotiate over project-specific requirements and outfitting. OVID, CMID and MISW

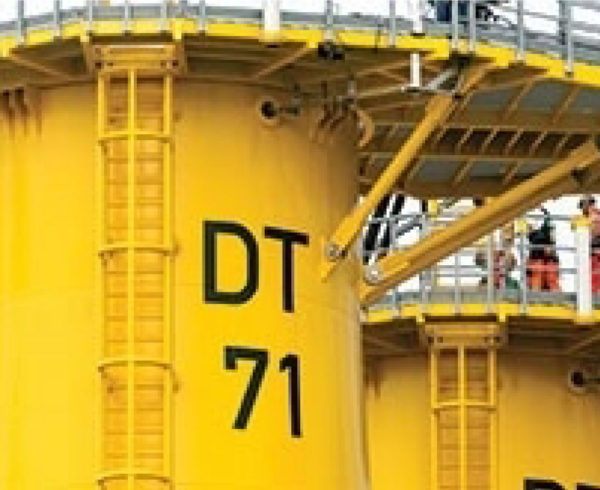

There are two common vetting systems used in the offshore oil & gas and marine construction industries; Offshore Vessels Inspection Database (OVID) from the Oil Companies International Marine Forum; and Common Marine Inspection Document (CMID) from the International Marine Contractors Association. OVID is a very intense program aimed at support vessels working in live oil & gas exploration and production fields, and is necessarily quite onerous on both the owner and the charterer, making it too heavy a tool to be utilised on the smaller, less sophisticated vessels of the marine construction industry. CMID however, is widely used in international marine construction as well as the offshore oil & gas and wind industries, and could present a more practical solution to civil construction on the West Coast. CMID has programs for both large and small vessels, with CMID M149 aimed at diving support, cable-laying, anchor

handling, offshore supply, heavy lift, survey/ seismic, oil recovery, LNG fuelled offshore vessels or jack-ups.

While the Marine Inspection for Small Workboats M189 (MISW) is specifically tailored for vessels supporting marine construction, as it is for non-SOLAS vessels < 24m and/or <500 GT, MISW can also be expanded with supplements for the following vessel types: dynamic positioning, towing, diving, anchor handling and non-self-propelled barges.

The CMID program has been described by the International Marine Contractors Association as an “ISM health check”. [Publisher’s note: the International Safety Management (ISM) Code is an international standard for the safe operation of ships and for pollution prevention. Chapter IX of the International Convention for the Safety of Life at Sea (SOLAS) requires compliance with the ISM Code.] This is particularly relevant here on the West Coast, where most small vessel operators do not have certified safety management systems and thus are caught unawares when faced with working for an international contractor. The CMID was developed in 1999 as an effort to provide a standard format for inspection of offshore vessels, and became an electronic system (eCMID) in 2009. The MISW was introduced in 2012 to bring the same standardization and quality to workboats and allow operators and charterers to properly understand and operate these vessels, most of which are non-SOLAS.

CMID in use

The philosophy behind the CMID program is that the vessel operator ensures that each vessel has a report completed annually by an accredited vessel inspector (AVI) who is independently assessed as competent in the specific inspection formats and subcategories. This report is then made available on request via the eCMID database to any potential charterer, eliminating the need and expense of completing another inspection. Many charterers will impose a six-month time limit on CMIDs prior to starting a contract but will usually then pay for an additional inspection.

Access to the CMID system is free, and one does not need to be an IMCA member to access it. The guidance documents can be downloaded free of charge from www.imcaecmid.com, or hard copies ordered for a nominal fee. There is a fee per inspection to upload the report to the database, 100 GBP ($170) for the CMID and 50 GBP ($85) per MISW, reflecting the shorter format of the latter. Accredited Vessel Inspectors (AVIs) are found via www.ecmidvesselinspectors.com. At present there are only two AVIs registered on the West Coast and another five in Eastern Canada, making large scale take-up of the system challenging until more achieve accreditation.

In use, vessel operators access the database and preload vessel and crew information for downloading by the appointed AVI, which reduces administration and time on board, and makes use of the system more affordable. Anyone who has interest in viewing an eCMID or eMISW sends a request to the vessel operator via the database, and the vessel operator grants approval. This allows brokers and potential charterers to vet vessels and operators without the additional expense and hassle of inspections.

A system that ensures standardized reports from competent accredited inspectors, which are available in a database, must fit in with the overall objective of running safe and on-budget projects. Although a standard vetting system is not currently in use on the West Coast, the benefits will surely make this a shortcoming soon to be rectified.

Philip Woodcock is the Director of newly founded marine consultancy, Wyndward Maritime Ltd. in Victoria BC. He is an Accredited Vessel Inspector who has several years experience performing CMID and MISW inspections, and has spoken and written on the benefits of the system in the European windfarm industry. He is not an employee of IMCA or OCIMF, and any statements made about those bodies are purely his own opinion.

Leave a Comment